During daily production, even a well-designed pop-up aluminum foil folding machine may encounter operational issues caused by raw materials, parameter settings, or long-term use.

Understanding common problems and knowing how to solve them helps manufacturers maintain stable output, reduce waste, and avoid unnecessary downtime.

This article summarizes the most common problems of pop-up aluminum foil folding machines and provides practical solutions based on real production experience.

Wrinkling Problems in Pop-up Aluminum Foil Sheet Production

Causes of Aluminum Foil Wrinkling

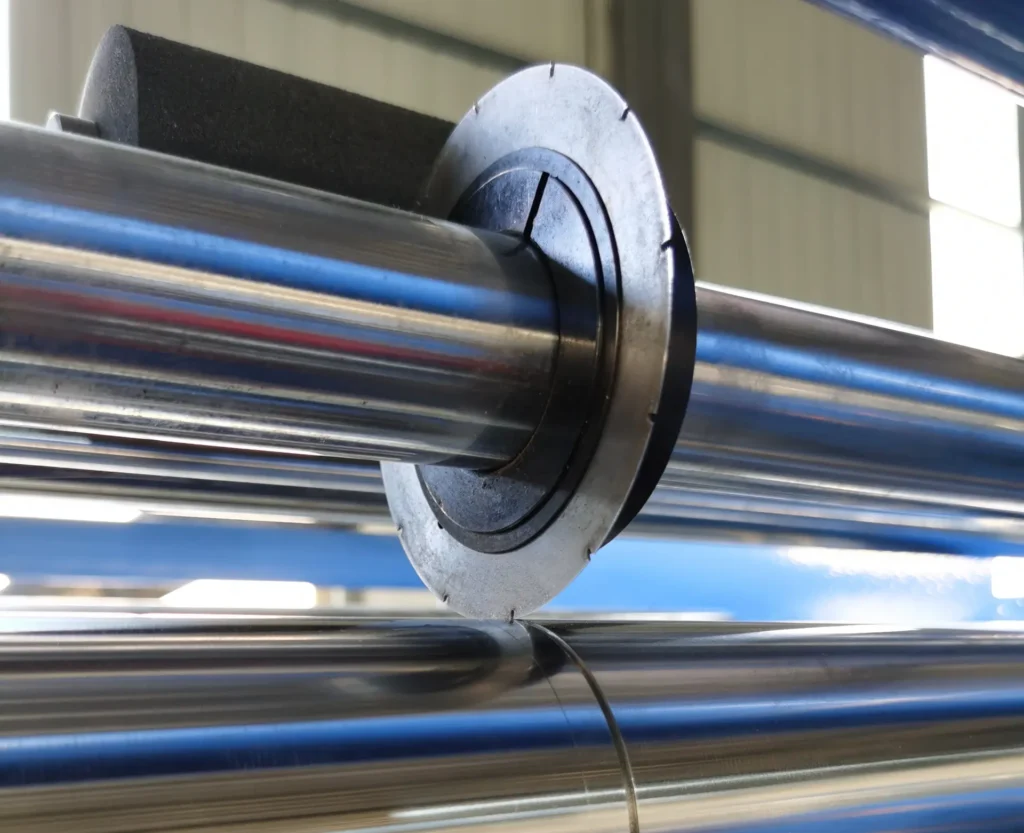

Wrinkling is one of the most frequent issues in aluminum foil processing and is usually caused by unstable tension during unwinding, incorrect alignment of the foil roll, or inconsistent foil thickness and raw material quality. Thin aluminum foil is especially sensitive to tension fluctuation at high production speed.

Solutions for Foil Wrinkling Problems

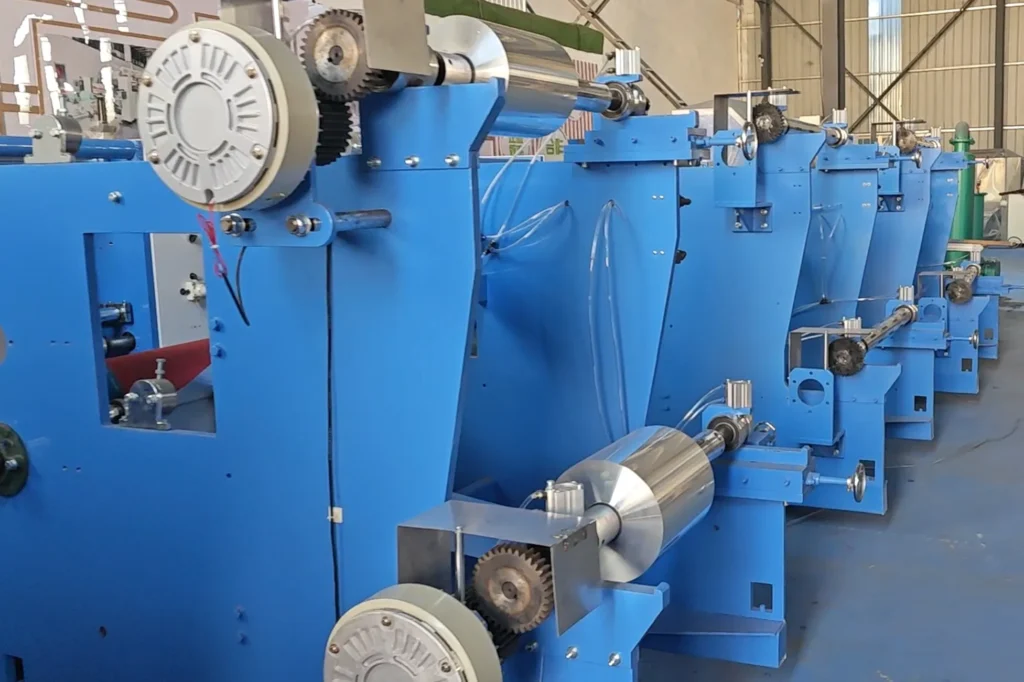

To solve wrinkling issues on a pop-up aluminum foil folding machine, the magnetic powder brake should be adjusted to maintain constant tension. The alignment of the air-expansion shaft should be checked, and raw material thickness consistency should be verified before production. Stable unwinding is the foundation of all downstream processes.

Folding Accuracy Issues in Pop-up Aluminum Foil Folding Machines

Why Folding Alignment Problems Occur

Poor folding alignment often results from insufficient vacuum pressure, contaminated perforated rollers, or incorrect folding angle settings. These factors directly affect whether sheets can be smoothly extracted one by one.

How to Improve Pop-up Folding Quality

For reliable pop-up performance, ensure the vacuum system operates at the recommended pressure, clean perforated rollers regularly, and fine-tune folding guides during machine setup. Vacuum-assisted folding is the key factor that differentiates pop-up sheets from ordinary foil sheets.

Cutting Problems in Aluminum Foil Folding Machines

Common Cutting Problems on Aluminum Foil Folding Machines

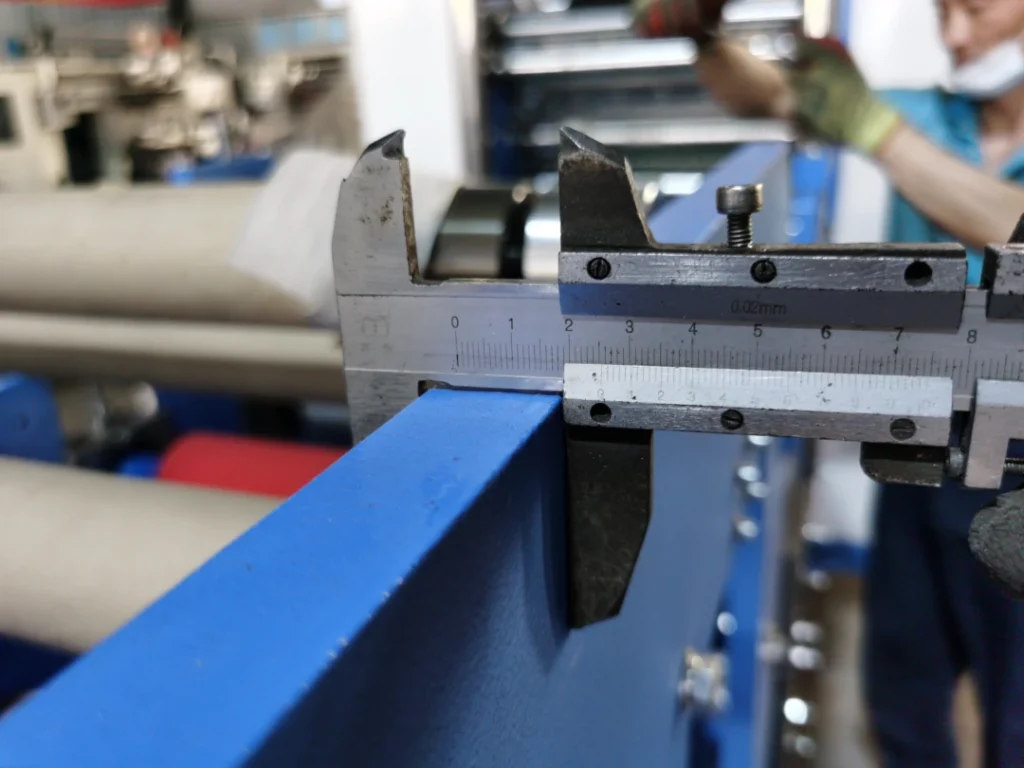

Cutting-related problems may include burrs on sheet edges, uneven cutting length, and increased foil dust. These issues usually occur when serrated cutting blades become worn or incorrectly installed.

Solutions for Cutting and Slitting Issues

To maintain cutting quality, serrated cutting blades should be replaced at regular intervals, blade installation must remain parallel and secure, and damaged or excessively thin foil should be avoided. Proper blade maintenance directly affects finished product appearance.

Counting Errors During Packaging

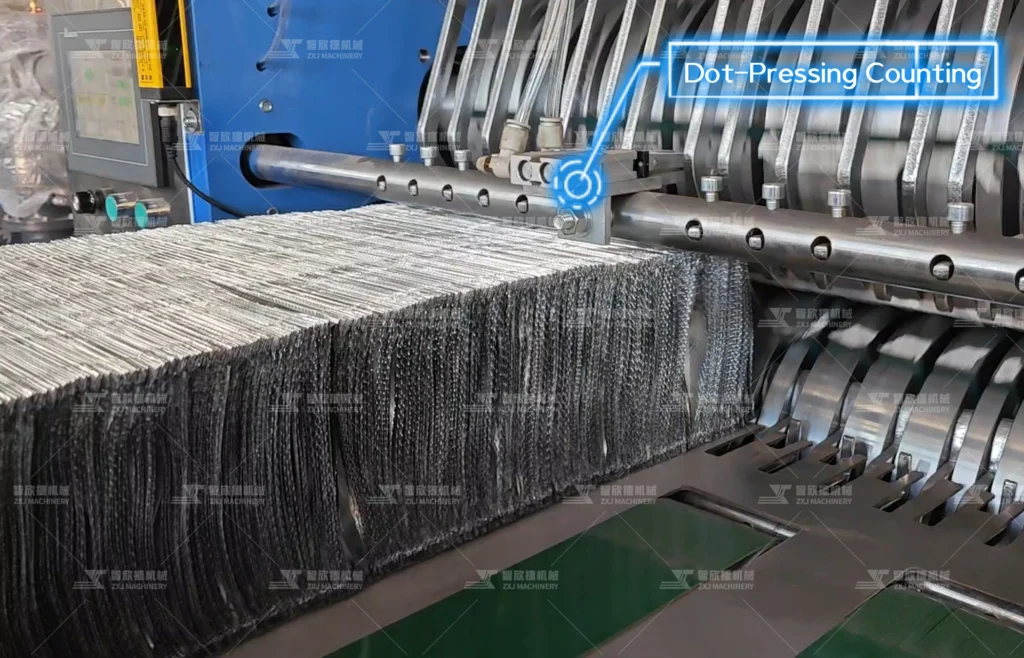

How Dot-Pressing Counting Works

Pop-up aluminum foil folding machines use a dot-pressing counting system, where a small dot is mechanically pressed onto the top sheet of each batch to indicate quantity. Standard counting accuracy is ±2 sheets per 500-sheet batch.

How to Reduce Counting Deviations

To maintain stable counting accuracy, ensure sheets are neatly aligned before dot pressing, check mechanical actuator timing, and avoid excessive vibration during high-speed operation. Our machine frame is manufactured with thicker steel plates compared to standard industry designs, ensuring enhanced structural rigidity and stable operation during high-speed production.

Frequent Machine Stops or Reduced Production Speed

Possible Causes of Unstable Operation

Unplanned stops may result from improper parameter settings, accumulated foil debris, or overloaded drive components during continuous operation.

Preventive Measures for Stable Operation

Routine cleaning and inspection should be performed, recommended speed ranges should be followed, and wear parts such as belts and blades should be monitored regularly. Preventive maintenance significantly reduces unexpected downtime.

How Proper Machine Selection Reduces Production Problems

Many operational issues originate from incorrect machine selection. To better understand machine structure and working principles, readers can refer to the article “Pop-up Aluminum Foil Folding Machine Overview: What It Is and How It Works.”

For guidance on selecting the right configuration, the article “How to Choose a Pop-up Aluminum Foil Folding Machine” explains capacity planning and model comparison in detail.

The full production workflow is explained in “The Complete Production Process of Pop-up Aluminum Foil Sheets.”

Conclusion

The production of pop-up aluminum foil sheets is a precision-driven process that combines tension control, embossing, cutting, vacuum folding, and accurate counting.

Each step plays a vital role in ensuring consistent product quality and reliable pop-up performance.

For manufacturers supplying food service, catering, and retail markets, understanding this process is the foundation for selecting the right equipment and achieving long-term production stability.

FAQ

What is the standard thickness for pop-up aluminum foil sheets?

Most pop-up foil sheets use aluminum foil with a thickness of 0.011–0.020 mm.

Why is vacuum folding important for pop-up foil sheets?

Vacuum folding ensures precise alignment so each sheet pulls out the next smoothly.

How are pop-up aluminum foil sheets counted?

Sheets are counted using a dot-pressing mechanism with ±2 sheets accuracy per 500 sheets.

Can one machine produce multiple sheet sizes?

Yes. Slitting and cutting configurations can be adjusted for different widths.

For production layout planning, machine specifications, or process consultation, feel free to contact our team for technical support.

for machine specifications, video demonstrations, and a detailed quotation.

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com

For detailed specifications and model options, visit our

🔗Aluminum Foil Folding Machine product page.