From roll feeding to fixed-length cutting and interfolding, learn the production process and technical advantages of a wax paper interfolder—and how to verify patent-backed originality.

Pop-Up Wax Paper Folding Machine: Production Process, Technical Advantages, and Patent Authenticity

When buyers evaluate a pop-up wax paper folding machine, they usually focus on output speed and finished sheet quality. That makes sense—your end customers want pre-cut deli paper that dispenses cleanly, one sheet at a time, without tearing, double-pulling, or wrinkling.

But there is a second layer that matters just as much: whether the machine design is truly engineered for stable interfolding—or simply a “look-alike” version that copies the appearance while failing in long-term production stability. In the pop-up market, imitation equipment is common. That’s why professional buyers increasingly ask about technical proof, real configuration details, and even patent-backed originality.

This article walks through the real production workflow of a pop-up wax paper folding machine, highlights the technical advantages that impact interfolding stability, and explains how to verify authenticity when the market is full of clones.

What an Interfolded Wax Paper Machine Produces (Pre-Cut Deli Paper Production)

An interfolded wax paper machine (also called a wax paper interfolder) converts roll stock into V-fold cross fold sheets designed for continuous extraction in dispenser boxes. This finished format is widely used for:

- Pre-cut deli paper production for sandwich counters and deli operations

- Interfolded burger wrap sheets for fast food and chain restaurants

- Pop-up dispensing sheets for bakery, food prep, and retail packaging

Unlike roll paper, pop-up sheets are a system product: the folding geometry and sheet-to-sheet overlap must be consistent, otherwise dispensing performance becomes unstable.

Technical Specifications (Model: YHZJ-PF-980)

Item | Specification |

Pop-up wax paper folding machine / interfolded wax paper machine | |

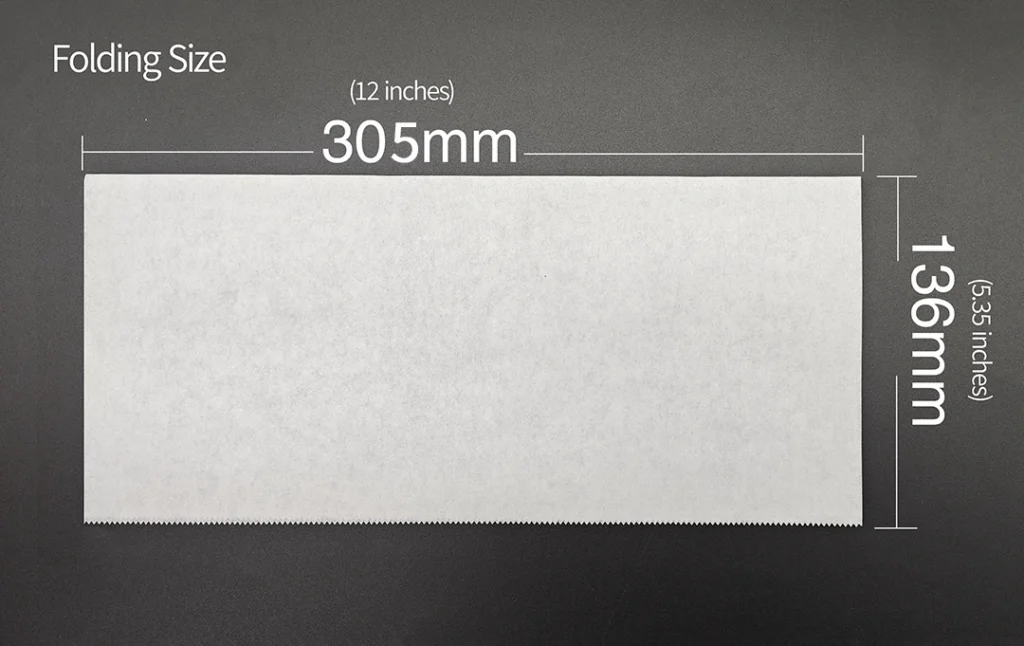

Finished sheet (unfold) | Length: 273 mm (customizable, fixed size); Width: 6”, 8”, 10”, 12”, 15” etc. |

Fold type | V-fold cross fold, continuous extraction type |

Applicable materials | 28–50 GSM silicone oil paper or wax paper |

Paper core | 76 mm (3 in.) |

Max raw roll | ≤ Φ1000 mm, max width 915 mm |

Output capability | Single column 300–400 sheets/min; common layouts: 305 mm 3 columns / 228 mm 4 columns |

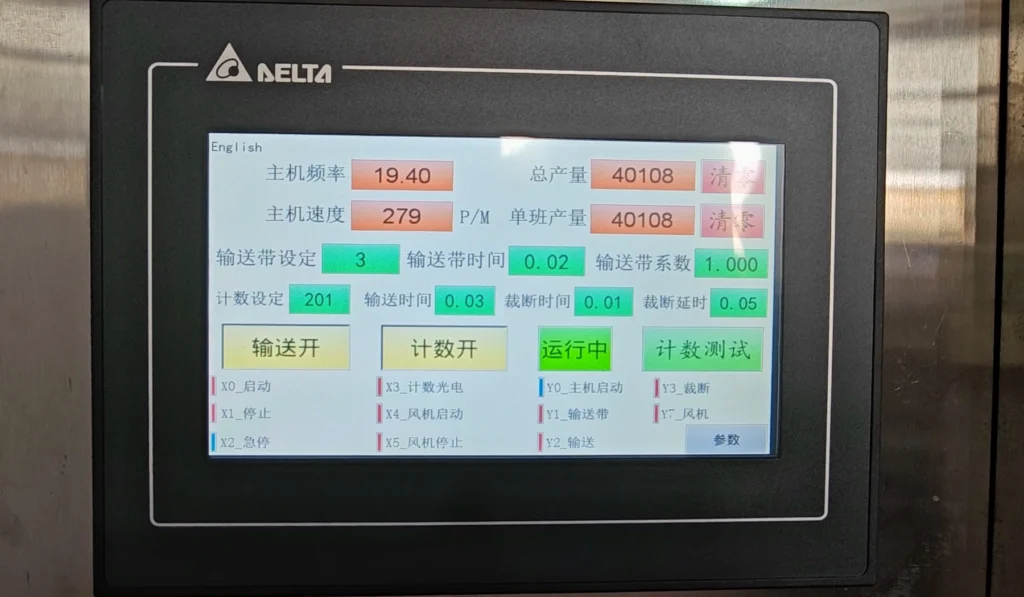

Control | 7-inch touch screen, touch control |

Power | Roots blower 22 kW; Main motor 4 kW; Tension motor 2 kW; Feed-out conveyor 400 W |

Machine size | Host: 6800×2150×2350 mm; Roots blower: 2300×800×2600 mm |

Gross weight | 6500 kg |

Pop-Up Wax Paper Folding Machine Workflow (Step-by-Step)

1) Roll feeding & material compatibility (wax paper / silicone oil paper)

For stable converting, the line starts with correct material handling. The equipment is specified for 28–5 0 GSM silicone oil paper or wax paper, using a 76 mm (3-inch) core. Max raw roll is ≤Φ1000 mm with maximum width 915 mm.

Why this matters: lightweight papers can wrinkle easily; heavier papers can resist folding. Matching the machine’s tension and folding design to your GSM range is a key success factor in sustainable, high-speed operation.

2) Fixed-length cutting for consistent pre-cut deli paper

The finished sheet length is typically 273 mm (customizable as a fixed size).

Fixed-length cutting is not “just a dimension”—it is the foundation for reliable packaging counts and consistent pop-up behavior. If sheet length drifts, overlap changes, and the dispenser experience degrades.

3) V-fold cross fold forming (core of pop-up performance)

The specified fold type is V-fold cross fold, continuous extraction type.

This is the mechanism that enables “one sheet pulls the next forward.” In practice, the fold must be sharp enough to hold shape, but not so aggressive that it causes tearing or memory curl.

4) Multi-column converting for throughput planning

Capacity comes from lane/column layout. The machine supports typical setups such as 305 mm 3 columns or 228 mm 4 columns, and a single column can reach 300–400 sheets/min depending on configuration and material.

For investors and OEM/ODM manufacturers, this is the key planning lever: you scale output by selecting the right width + column layout rather than pushing a single lane beyond its stability window.

5) Touch control, stable batching, and discharge

The system uses a 7-inch touch screen for operation and settings

In real production, stable batching is what protects your downstream packing—especially if you integrate the machine into an automatic food packaging line.

Technical Advantages That Reduce Labor in Deli Paper Packaging

Advantage 1: Designed for one-at-a-time dispenser paper machine performance

Pop-up products succeed or fail at the dispenser. Stable extraction requires consistent overlap and folding repeatability. The machine is purpose-built for continuous extraction sheets (V-fold cross fold).

Advantage 2: High-speed paper converting with controlled airflow and tension

A key part of stable folding at speed is controlling the web during cutting and forming. The system includes a Roots blower (22 kW) plus main drive and tension motor power, supporting stable handling for pop-up folding and discharge.

Advantage 3: Production-ready footprint and utility planning

From a factory planning perspective, buyers need clear equipment footprint and utilities:

- Host: 6800×2150×2350 mm

- Roots blower: 2300×800×2600 mm

- Gross weight: 6500 kg

This transparency helps you evaluate installation, line layout, and maintenance access—critical for enterprise procurement.

Patent Authenticity: How to Reduce Risk from Imitation Machines

Here’s the reality: as pop-up demand grows, the market tends to produce “similar-looking” machines. Some may work for short trial runs but fail in long-term stability, accuracy, or serviceability.

Our pop-up wax paper folding machine is protected by a China invention patent (official grant under China’s patent system).

- Patent type: China Invention Patent

- Patent No.: CN 117963621 B

How buyers can verify authenticity (practical due diligence):

- Request the patent certificate copy and match the patent number + applicant name.

- Check the patent status using official channels (CNIPA database) with the patent number.

- Ask for videos showing stable interfolding at your target GSM and widths, not just idle running.

- Confirm spare parts and wear parts list, plus service capability for commissioning and training.

This approach protects your investment and ensures you get a machine that is engineered—not improvised.

FAQ

What is an interfolded wax paper machine used for?

It converts roll wax/silicone oil paper into interfolded pop-up sheets for dispenser boxes—ideal for pre-cut deli paper production.

Can this pop-up wax paper folding machine produce one-at-a-time dispenser paper?

Yes, the V-fold cross fold format is designed for continuous extraction, supporting one-at-a-time dispensing performance.

What GSM wax paper can the machine run?

The specified applicable range is 28–50 GSM wax paper or silicone oil paper.

What sheet sizes are supported for pre-cut deli paper?

Standard length is 273 mm (fixed, customizable), with common widths 6”–15”.

How do I choose 3-column vs 4-column output?

It depends on target sheet width and capacity planning. Typical setups include 305 mm 3 columns or 228 mm 4 columns.

Can this be integrated into an automatic food packaging line?

Yes—commonly integrated with boxing/cartoning and downstream packing to reduce labor in deli paper packaging (final layout depends on your plant workflow).

Is this suitable for butcher paper?

This model is specified for 28–50 GSM wax/silicone oil paper. For butcher paper (often heavier), we recommend confirming GSM and stiffness first.

📩 Get a Quote / Contact Us

for machine specifications, video demonstrations, and a detailed quotation.

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com

For detailed specifications and model options, visit our

🔗Interfolded Deli Paper Production Line