The Complete Production Process of Pop-up Foil Sheets

Understanding the production process of pop-up aluminum foil sheets is essential for manufacturers aiming to deliver consistent quality, stable extraction performance, and efficient packaging.

From raw aluminum foil rolls to neatly stacked pop-up sheets, each step in the process directly affects the final product.

This article provides a step-by-step overview of how pop-up aluminum foil sheets are produced using a professional pop-up aluminum foil folding machine.

Raw Material Preparation in the Pop-up Foil Sheets Production Process

The production process starts with selecting suitable aluminum foil raw material.

Most pop-up aluminum foil sheets are produced from:

- Single-layer aluminum foil

- Thickness range: 0.011–0.020 mm

- Standard paper core sizes (3 inch / 6 inch)

Stable raw material quality ensures smooth unwinding and reduces the risk of wrinkles or tearing during high-speed production.

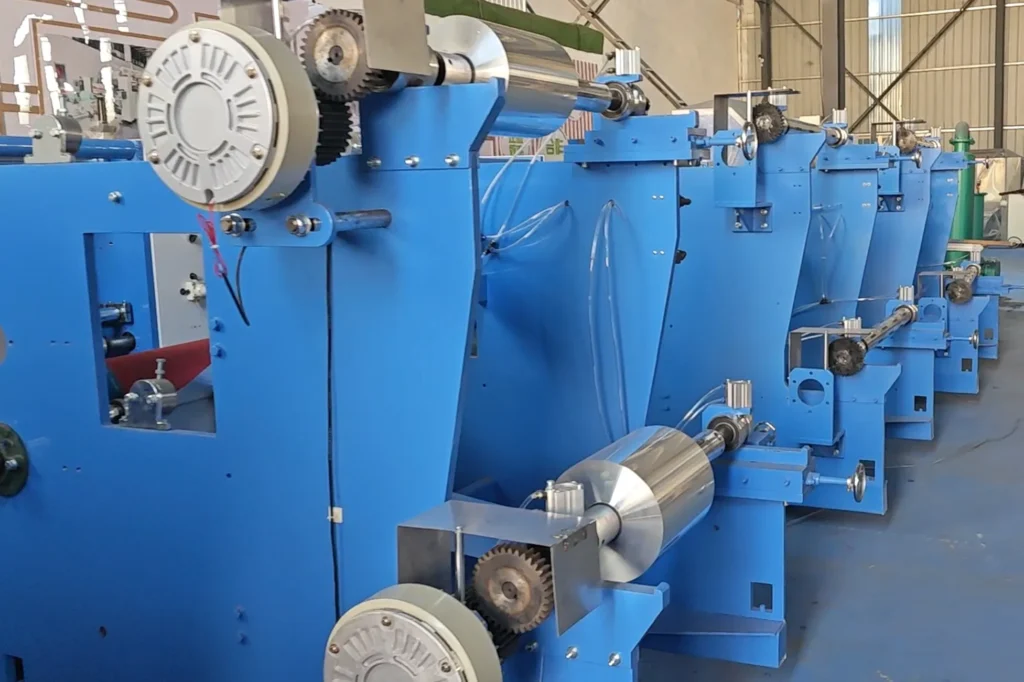

Tension-Controlled Unwinding for Aluminum Foil Processing

During the pop-up aluminum foil sheets production process, consistent tension is critical.

Professional machines use:

- Magnetic powder brake systems

- Air-expansion shafts for stable roll mounting

This combination keeps the foil under constant tension, preventing stretching and ensuring accurate sheet length during downstream processing.

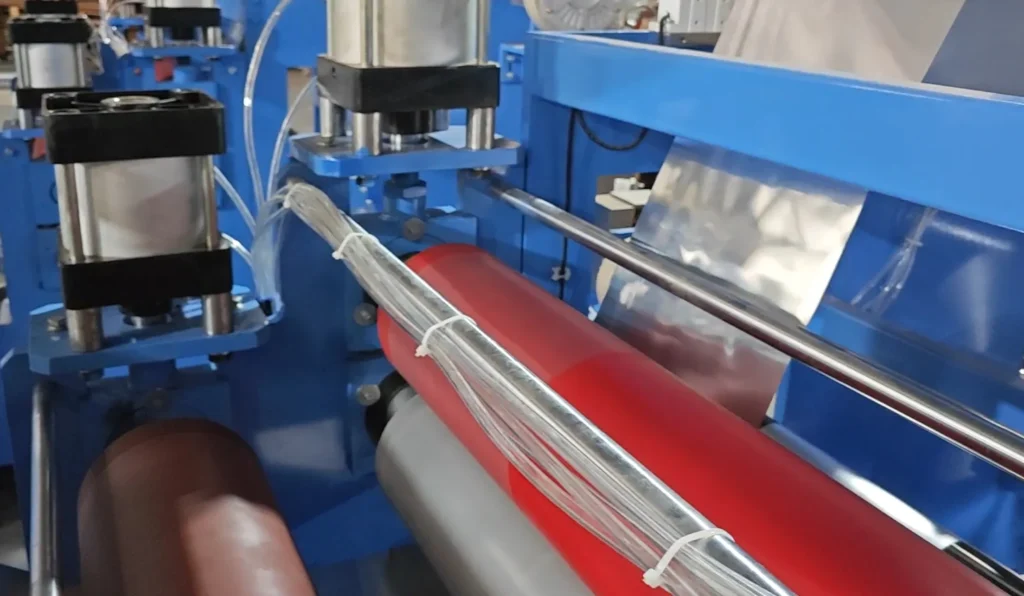

Embossing in the Pop-up Aluminum Foil Sheets Production Process

Steel Roller and Rubber Roller Embossing Structure

Embossing is applied using a steel roller paired with a rubber roller.

This step improves:

- Foil rigidity

- Sheet separation

- Surface appearance

Diamond or custom embossing patterns are commonly used to enhance both functionality and aesthetics.

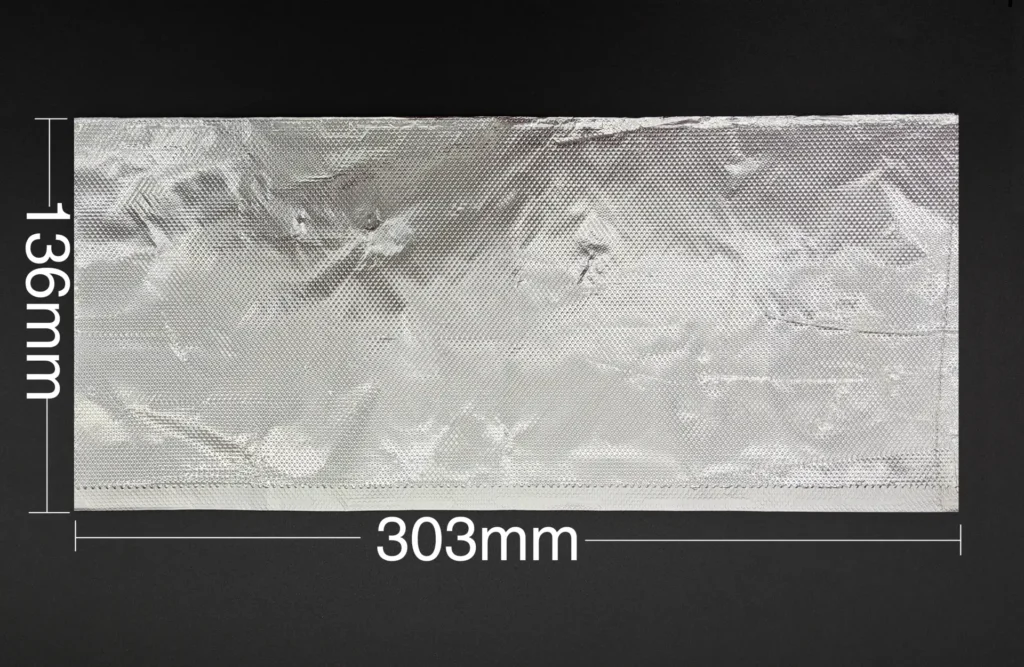

Slitting and Cutting in the Aluminum Foil Sheets Production Process

Multi-Lane Slitting Configuration

Depending on the target sheet size, the foil web is slit into multiple lanes, typically:

- 228 mm=9 inch

- 305 mm=12 inch

Multi-lane slitting increases output without compromising stability.

Serrated Cutting for Clean Sheet Edges

Serrated cutting blades are used to produce clean, uniform edges.

Cutting accuracy is maintained throughout long production runs to ensure consistent folding and extraction.

Vacuum Folding Technology for Pop-up Foil Sheets

Vacuum-assisted folding is the core technology behind pop-up functionality.

Using perforated rollers and a controlled vacuum system:

- Sheets are folded into precise V-fold and cross-fold patterns

- Each sheet is positioned to pull out the next

This step determines whether the final product performs smoothly in real kitchen and catering environments.

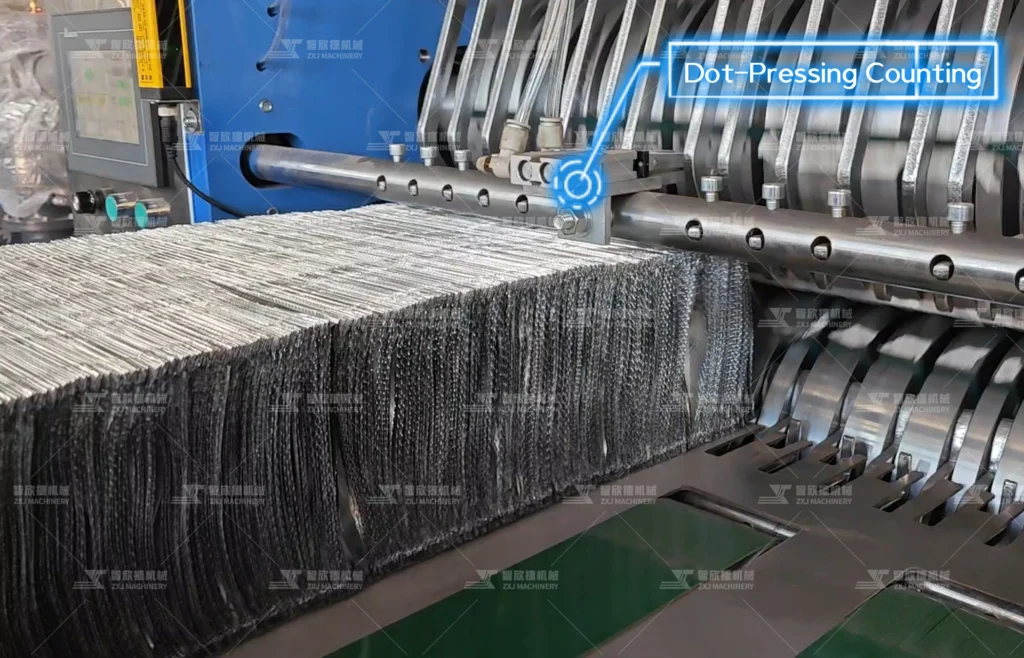

Dot-Pressing Counting in the Pop-up Foil Sheets Production Process

Instead of optical sensors or label insertion, pop-up aluminum foil sheets are counted using a dot-pressing mechanism.

After sheets are neatly stacked:

- A mechanical device presses a small dot on the top sheet

- Each dot represents a completed batch

The system achieves ±2 sheets accuracy per 500-sheet batch, providing reliable identification for packaging without complex electronics.

Finished Stack Output and Packaging Preparation

Once counting is completed, finished stacks are discharged automatically.

At this stage:

- Sheets are aligned and ready for manual or automatic packaging

- Stack consistency ensures smooth downstream box loading

This final step directly affects packing speed and labor efficiency.

How the Production Process Relates to Machine Selection

To fully understand the equipment behind this process, you may refer to:

👉 Internal Link Anchor ①

Pop-up Aluminum Foil Folding Machine Overview: What It Is

👉 Internal Link Anchor ②

How to Choose a Pop-up Aluminum Foil Folding Machine

These articles explain machine structure and selection criteria in more detail.

Conclusion

The production of pop-up aluminum foil sheets is a precision-driven process that combines tension control, embossing, cutting, vacuum folding, and accurate counting.

Each step plays a vital role in ensuring consistent product quality and reliable pop-up performance.

For manufacturers supplying food service, catering, and retail markets, understanding this process is the foundation for selecting the right equipment and achieving long-term production stability.

FAQ

What is the standard thickness for pop-up aluminum foil sheets?

Most pop-up foil sheets use aluminum foil with a thickness of 0.011–0.020 mm.

Why is vacuum folding important for pop-up foil sheets?

Vacuum folding ensures precise alignment so each sheet pulls out the next smoothly.

How are pop-up aluminum foil sheets counted?

Sheets are counted using a dot-pressing mechanism with ±2 sheets accuracy per 500 sheets.

Can one machine produce multiple sheet sizes?

Yes. Slitting and cutting configurations can be adjusted for different widths.

For production layout planning, machine specifications, or process consultation, feel free to contact our team for technical support.

for machine specifications, video demonstrations, and a detailed quotation.

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com

For detailed specifications and model options, visit our

🔗Aluminum Foil Folding Machine product page.