Introduction

The pop-up foil folding machine is designed for efficient production of pre-cut and interfold aluminum foil sheets. It transforms jumbo foil rolls into neatly folded, ready-to-use sheets commonly used in food packaging, catering, and household applications. With compact structure and precision control, this equipment ensures consistent output, minimal waste, and hygienic handling.

Functions and features:

1.Magnetic powder brake and gas expansion shaft to complete the raw material release;

2.Steel roller and polyurethane roller embossing device, the pattern clearly;

3.Cutting knife stab cutting, folding with vacuum adsorption (roots vacuum system);

4.Automatic counting and sub bit setting output;

5.Using variable frequency motor drive, speed can be adjusted;

6. Touch screen control device operation

7. Equipped have two emergency stop switch

8. The embossing frame is outer, so that the embossing roller can be replaced conveniently

9. Counting by labeling paper,can be set in touch screen

Technical Specifications

Model | YHZJ -AIF 680The roller surface width is 680mm The maximum pass width is 610mm | YHZJ -AIF 980The roller surface width is 980mm The maximum pass width is 915mm |

Shearing length | 273 mmCutting-off length of the product is 273mm, ±2mm; | |

After folding length | 273 mm product after folding length is 137mm | |

Shape of the finished product | V-fold cross fold, continuous extraction type273 mmProduct advise edge is 3-10mm adjustable | |

Cut off the method | Serrated cut | |

Embossing device | The equipment is equipped with one pairs of steel roller and rubber roller,diamond-type lattice(can change) | |

Suitable raw material | 0.011-0.020mm single-layer aluminum foil with a thickness tolerance of ±5% | |

Specification of raw paper core | 76 mm( 3 inches) | 150 mm( 6 inches) |

Raw material size | ≤Φ800 mm×Max width 610mm | ≤Φ800mm×Max width 915mm |

Process capability | Single line 400-500 sheets/min*2 lines =1000 sheets/min | Single line 400-500 sheets/min*3/4 lines =1500-2000 sheets/min |

Cutting width | 228mm/305 mm* 2linesSlitting with connecting points | 228 mm*4lines/305 mm*3lines, Slitting with connecting points |

Power required | Main motor 380V 50Hz 4 KW Tension motor 380V 50Hz 1KW Draught fan 380V 50Hz 15 KW | Main motor 380V 50Hz 4 KW Tension motor 380V 50Hz 1KW Draught fan 380V 50Hz 18.5 KW |

weight | 4500kg | 5500kg |

Machine size | 4050*1850*1750mm | 4050*2150*1750mm |

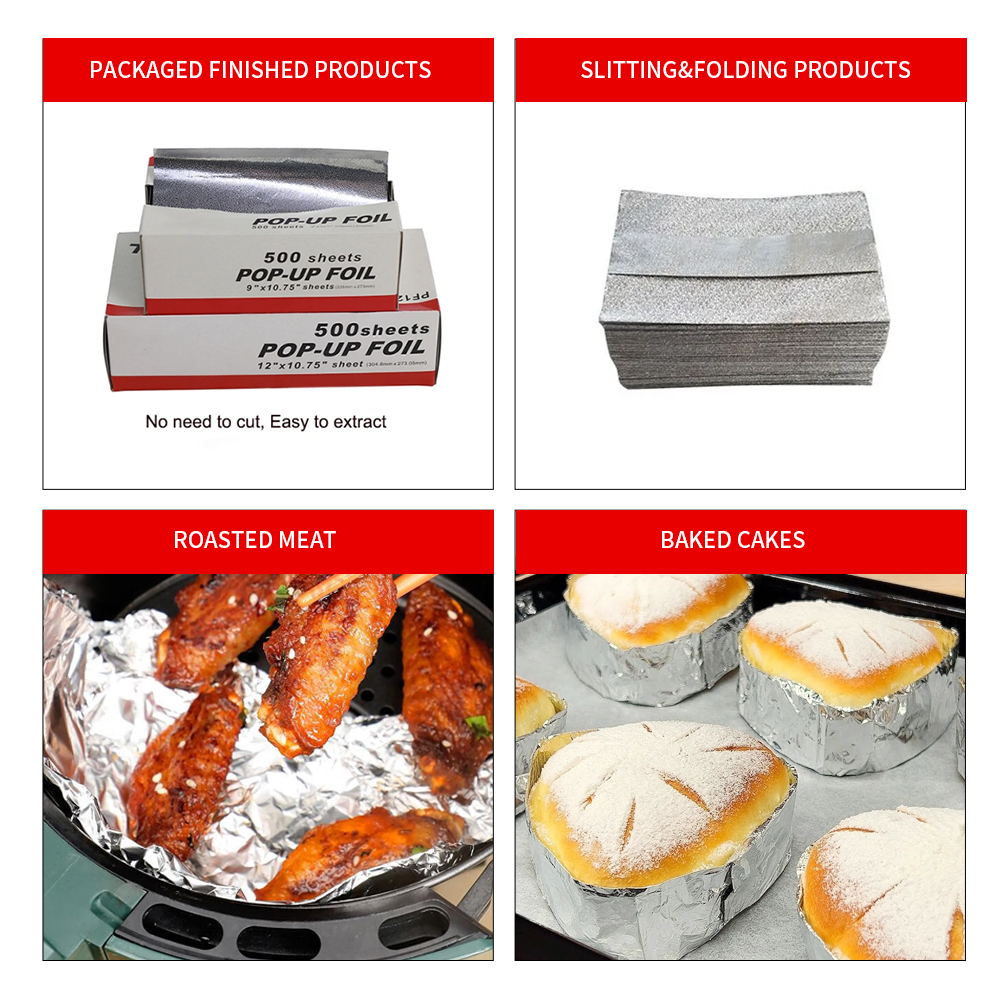

Aluminum foil Applications

Pop-up foil sheets are widely used in:

- Food packaging – restaurants, bakeries, catering services.

- Household products – disposable kitchen wraps.

- Industrial use – laboratory or cleanroom material handling.

- Hairdressing industry – hairdressing pop-up foils used in salons for highlighting, coloring, and bleaching hair, providing clean and easy tear-off application.

Maintenance and Operation Tips

Regularly clean the foil feed rollers to prevent residue buildup. Lubricate mechanical parts every 500 hours of operation. Always check the cutting blade alignment before production to ensure fold accuracy.

External References

For further insights into pop-up foil applications and standards, refer to:

Conclusion

The Pop-up Foil Folding Machine combines precision engineering, user-friendly control, and customizable configuration to streamline foil sheet production for diverse applications. Whether for catering suppliers or foil product manufacturers, this machine delivers stable performance and operational efficiency.

👉 Explore more aluminum foil machine models and complete production solutions here:

https://www.zxjmachinery.com/aluminum-foil-machine/

Optional FAQ Section

- What is the maximum speed of the pop-up foil folding machine?

– Up to 2000 sheets per minute depending on foil width and lane number. - What type of folding method does this machine use?

– Both models use a V-fold cross type with continuous pop-up extraction, ensuring easy sheet pulling from dispenser boxes. - What foil thickness is supported?

– Typically 0.010–0.020 mm. - Is CE certification available?

– Yes, CE and ISO9001 certification available upon request. - Can it connect with an automatic packing line?

– Yes, we can provide inline integration with box packing units.

For detailed specifications, pricing, or demo scheduling

Or contact our engineering team directly:

- Email: paul@zxjmachinery.com

- WhatsApp: +86 158-9610-9075

Learn more about working principles in our

🔗Pop-up Aluminum Foil Folding Machine overview article.