Choosing the right Emergency Blanket Folding Machine is important for manufacturers. You want to balance output, precision, and production cost.

With many Emergency blanket folding machines available on the market, the goal is not simply choosing a machine—it is selecting the right machine that truly fits your production needs.

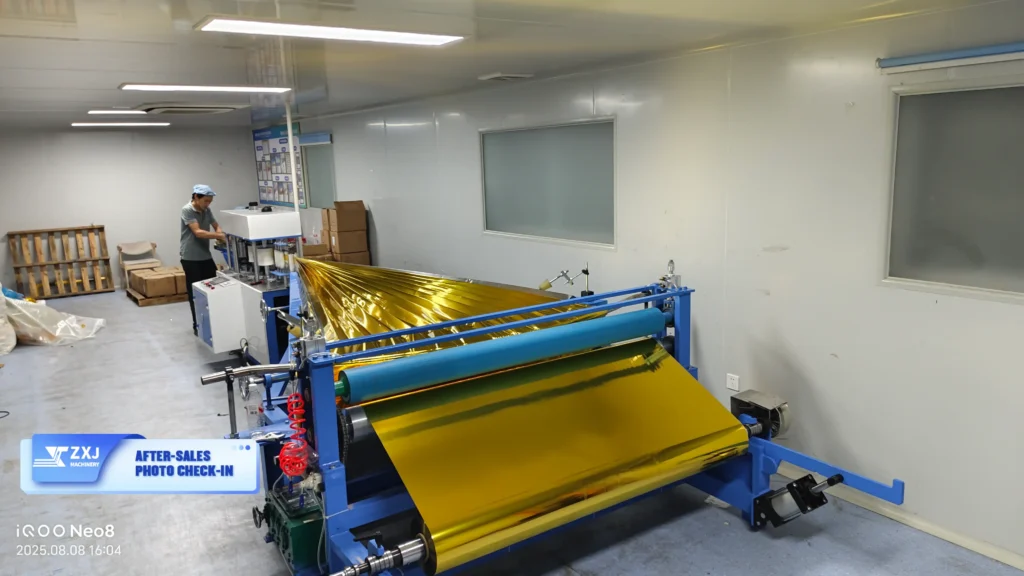

In China, a significant majority of emergency blanket folding machines are manufactured by our facility, where we have developed and refined this technology for years. While similar-looking machines exist in the market, most are imitations of our earlier designs and do not match the engineering stability, material quality, or long-term performance of our patented systems.

1. Define Your Production Needs

Before comparing equipment, start with a clear understanding of your production goals.

Key questions include:

- What blanket sizes do you produce?

- What material do you use—vacuum aluminized film, PET film, or PE-laminated foil?

- How many hours per day will the machine run?

- What is your target output volume?

- How much space is available in your workshop?

Large manufacturers that export to multiple markets often need continuous production with stable feeding and accurate perforation. Smaller factories may prefer simpler systems that are easier to operate and maintain.

2. Focus on Key Technical Features

Folding machines differ greatly in their design philosophy, engineering quality, and operational performance. Factors such as folding accuracy, material stability, long-term durability, and ease of maintenance can vary widely between manufacturers.

Understanding these differences is essential, because the right folding system not only improves current output but also affects your long-term production efficiency, labor cost, and quality consistency.

The following key considerations will help you evaluate each machine more effectively and determine which solution truly aligns with your factory’s production goals.

Folding Accuracy

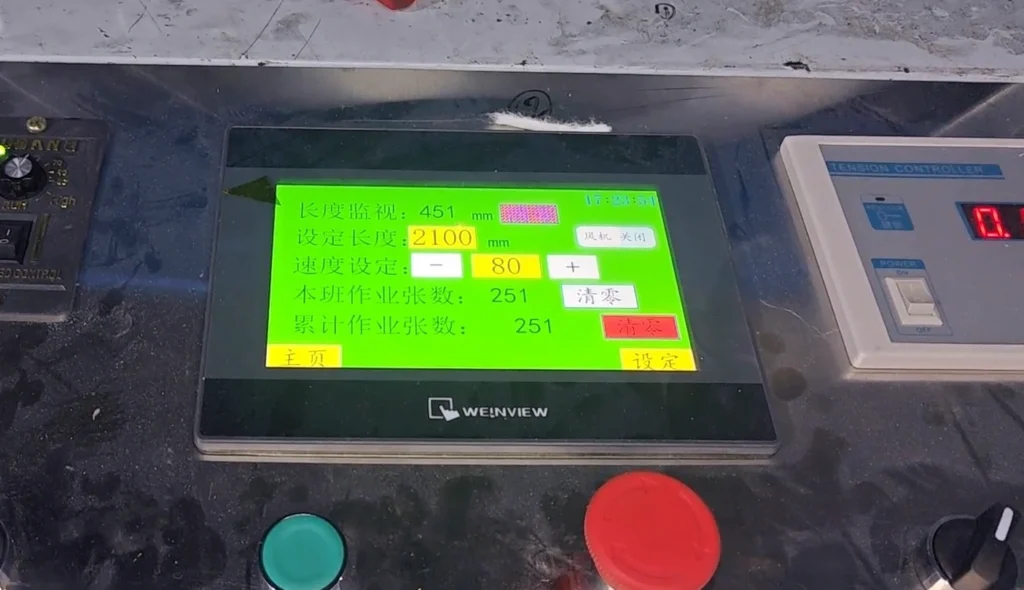

Accuracy determines consistency. Look for machines that maintain ±3 mm precision at high speed. Accurate folding reduces waste and ensures every blanket meets customer standards.

Production Speed

High-volume producers should look for speeds around 60~80 meters per minute. A good machine keeps high speed without losing accuracy.

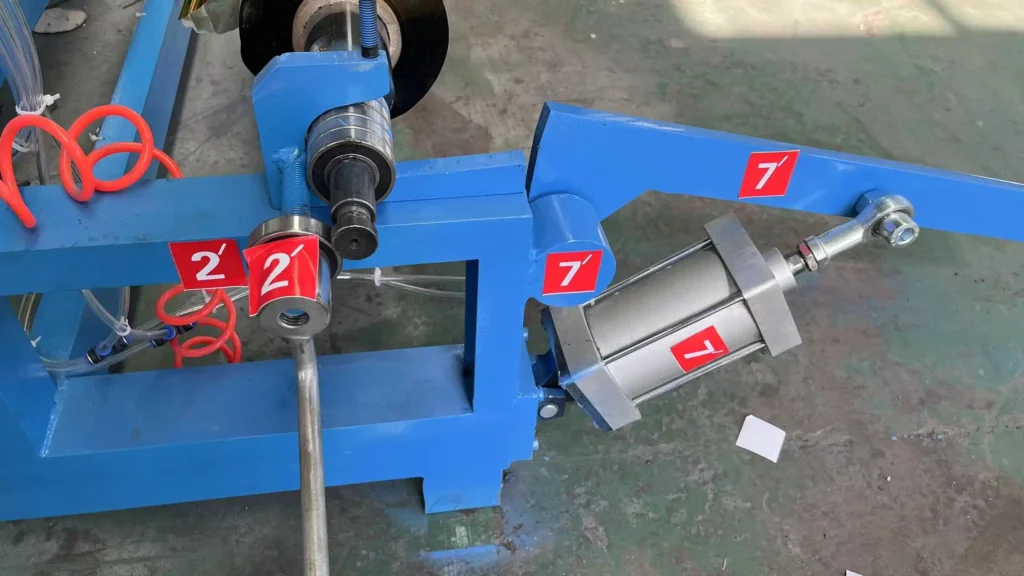

Tension Control System

Film materials are thin and easy to wrinkle. Systems with pneumatic tailstock and magnetic brake control keep the material smooth during feeding. This prevents stretching and improves fold alignment.

Fixed-Length Perforation

Reliable perforation helps workers separate finished blankets quickly. Standard settings are 1.3 m or 1.6 m per sheet.

Fixed-length perforation also helps counting and packaging, especially when producing large batches.

Ease of Operation

Modern machines should include a simple control panel, servo motors, and easy-to-adjust parameters.

Your operators should be able to change blanket sizes or adjust the perforation length without long downtime.

3. Compare Different Machine Types

The table below shows how automated systems compare with semi-automatic and manual options:

Feature | ZXJ YWJ-JJT-1600 | Semi-Auto Models | Manual Folding |

Accuracy | ±3 mm | ±10 mm | Variable |

Speed | 60 m/min | 15–25 m/min |

<10 m/min

|

Labor | 1 operator | 3–4 operators | 5+ operators |

Perforation | Built-in | Optional | None |

Consistency | High | Medium | Low |

From this comparison, it becomes clear that automated systems deliver the highest long-term value. They increase speed, reduce labor costs, and improve batch consistency.

4. Plan for Future Expansion

When choosing your folding machine, think beyond your current needs. Consider a system that delivers long-term stability, reduces unexpected downtime, and minimizes maintenance-related production losses.

Look for:

- High equipment stability: A reliable folding system maintains consistent performance under continuous operation and reduces the likelihood of breakdowns.

- Reduced maintenance frequency: Maintenance interrupts production. A stable machine helps avoid unnecessary downtime, preserving output capacity.

- Robust machine structure: ZXJ Machinery uses higher‑grade materials and thicker metal plates—2 mm to 4 mm thicker than many competing manufacturers—resulting in stronger frames and more stable operation.

- Lower failure rate: In real production environments, ZXJ emergency blanket folding machines have demonstrated a 5%–15% reduction in failure rates, helping factories achieve more predictable and efficient production schedules.

ZXJ Machinery’s patented machine (CN109677990B) is built for long-term reliability. Its reinforced structure, stable folding mechanism, and durable components ensure smooth operation as your production capacity grows.

5. Work With an Experienced Manufacturer

A machine is only as reliable as the company behind it.

When selecting a supplier, make sure they can provide:

- Experience with emergency blanket production

- In-house research and development

- Patent-backed technology

- ISO-certified manufacturing

- Reliable after-sales support and spare parts

- Real installation cases in multiple countries

ZXJ Machinery, a China National High-Tech Enterprise, supplies machines to manufacturers across Asia, the Middle East, and Europe.

Our unique folding mechanism is renowned for its stability, precision, and durability.ur production line with patented folding technology?

Looking for the right folding solution for your factory?

for machine specifications, video demonstrations, and a detailed quotation.

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com