Choosing the right pop-up aluminum foil folding machine is a critical decision for manufacturers supplying food service, catering, and retail markets.

For factory owners and procurement managers the selection directly affects production efficiency, product consistency, labor cost, and long-term operational stability.

This buyer’s guide explains how to evaluate a pop-up aluminum foil folding machine based on real production requirements, with a clear comparison of the AIF-680 and AIF-980 models.

Why Choosing the Right Pop-up Aluminum Foil Folding Machine Matters

A pop-up aluminum foil folding machine is not a standard converting machine. It must deliver:

- Stable tension control for thin aluminum foil

- Accurate folding alignment for continuous pull-out

- Consistent counting for packaging

- Reliable performance at high speed

An unsuitable machine may cause foil wrinkling, uneven folding, inaccurate counts, and frequent downtime—leading to rejected batches and higher operating costs.

Before comparing prices, buyers should focus on machine structure, capacity, and process stability.

Key Factors to Consider When Selecting a Pop-up Aluminum Foil Folding Machine

Production Capacity and Output Requirements

Production capacity is the first decision point.

- Medium-scale factories typically require 800–1000 sheets/min

- High-volume suppliers often need 1500–2000 sheets/min

The machine must maintain stable folding quality even at maximum speed.

Always confirm whether the quoted speed refers to single-lane or multi-lane output.

Aluminum Foil Thickness and Material Compatibility

A professional aluminum foil folding machine should handle:

- Single-layer aluminum foil

- Typical thickness range: 0.011–0.020 mm

- Stable unwinding without stretching or tearing

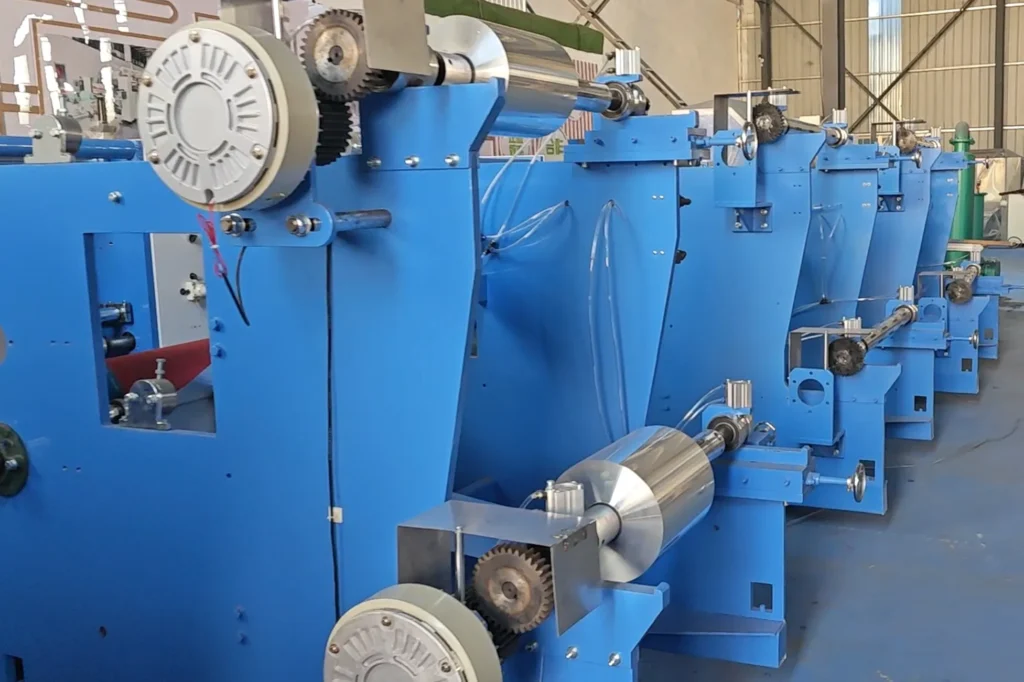

Machines equipped with magnetic powder brake tension control provide more reliable results for thin foil commonly used in food packaging.

Folding Method and Pop-up Performance

The folding system determines whether the finished sheets can be smoothly extracted one by one.

Look for machines using:

- Vacuum-assisted folding

- Perforated rollers with uniform suction

- Stable V-fold and cross-fold geometry

This ensures consistent pop-up performance for end users in kitchens and catering environments.

Cutting Accuracy and Slitting Configuration

Accurate cutting affects both appearance and usability.

A quality pop-up foil folding machine should include:

- Serrated cutting blades for clean edges

- Flexible slitting options (228 mm =9 inch / 305 mm =12 inch)

- Multi-lane configurations to increase output

Cutting tolerance should remain stable during long production runs.

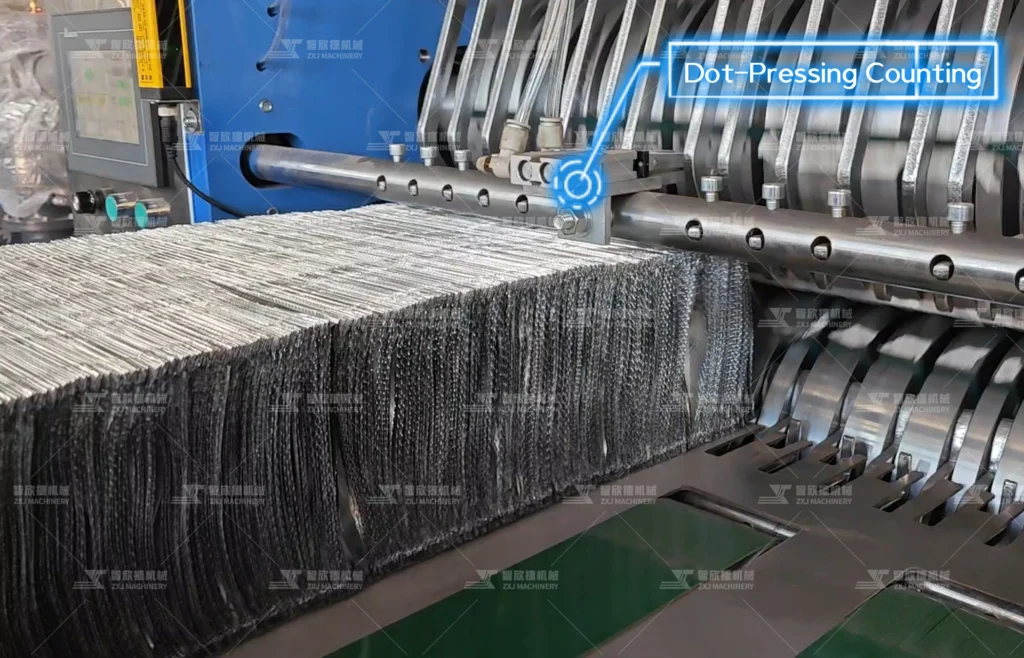

Counting Method and Packaging Consistency

Pop-up aluminum foil machines typically use dot-pressing counting systems.

After sheets are neatly stacked, a mechanical device presses a small dot on the top of each batch to indicate quantity.

A reliable system achieves ±2 sheets accuracy per 500-sheet batch, ensuring packaging consistency without complex sensors or electronics.

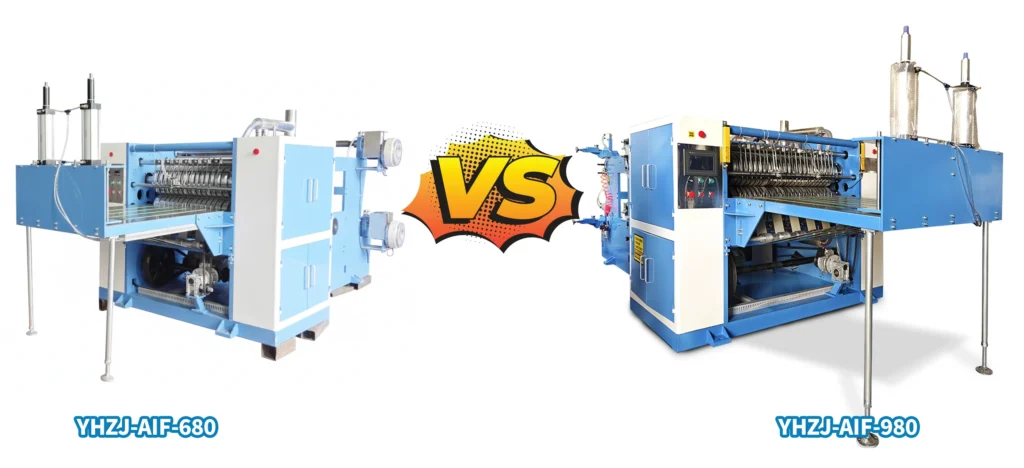

Choosing Between 680 and 980 Pop-up Aluminum Foil Folding Machines

680 Model Pop-up Aluminum Foil Folding Machine

The AIF-680 model is suitable for:

- Medium production volumes

- Limited factory space

- Flexible product specifications

Typical advantages include lower energy consumption and easier operation for smaller teams.

980 Model Pop-up Aluminum Foil Folding Machine

The AIF-980 model is designed for:

- High-output factories

- Multi-lane production

- Large export orders

With a wider working width and higher speed, it is ideal for manufacturers supplying supermarkets, distributors, and private-label brands.

Compliance, Safety, and Long-Term Reliability

For buyers in North America, Europe, and the Middle East, machine reliability and compliance are essential.

When selecting a pop-up aluminum foil folding machine, confirm:

- CE-compliant electrical and safety design

- Emergency stop systems

- Stable mechanical structure for long-term operation

- Availability of spare parts and technical support

A machine should be evaluated as a long-term production asset, not just a one-time purchase.

How This Guide Connects to the Machine Working Principle

If you want a deeper technical explanation of machine structure, folding process, and key components, you can read our detailed article:

👉 Internal Link Anchor

Pop-up Aluminum Foil Folding Machine Overview: What It Is and How It Works

Conclusion

Selecting the right pop-up aluminum foil folding machine requires more than comparing prices. Production capacity, folding stability, counting accuracy, and long-term reliability all play a decisive role in total manufacturing cost.

By choosing the correct configuration—whether AIF-680 or AIF-980 model—manufacturers can achieve stable output, consistent product quality, and efficient packaging performance.

FAQ

What is the best pop-up aluminum foil folding machine for high-volume production?

For high-output factories, the 980 model is generally recommended due to its wider working width and higher production speed.

What aluminum foil thickness can the machine handle?

Most machines support single-layer aluminum foil from 0.011 mm to 0.020 mm thickness.

How accurate is the counting system?

The dot-pressing counting system achieves ±2 sheets accuracy per 500-sheet batch.

Is vacuum folding necessary for pop-up foil sheets?

Yes. Vacuum-assisted folding ensures consistent pop-up performance and smooth sheet extraction.

Can one machine produce different sheet widths?

Yes. Slitting configurations can be adjusted to produce different widths such as 228 mm and 305 mm.

FAQ

What is the best pop-up aluminum foil folding machine for high-volume production?

For high-output factories, the 980 model is generally recommended due to its wider working width and higher production speed.

What aluminum foil thickness can the machine handle?

Most machines support single-layer aluminum foil from 0.011 mm to 0.020 mm thickness.

How accurate is the counting system?

The dot-pressing counting system achieves ±2 sheets accuracy per 500-sheet batch.

Is vacuum folding necessary for pop-up foil sheets?

Yes. Vacuum-assisted folding ensures consistent pop-up performance and smooth sheet extraction.

For detailed specifications, model recommendations, or a customized solution, feel free to contact our team for technical consultation.

for machine specifications, video demonstrations, and a detailed quotation.

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com

For detailed specifications and model options, visit our

🔗Aluminum Foil Folding Machine product page.