Emergency blankets, also known as first-aid blankets or space blanket, are essential in survival, rescue, and medical care. Their thin, reflective design helps retain body heat and protect against wind, rain, and cold. But behind every compact, perfectly folded blanket lies a precise, automated manufacturing process powered by specialized equipment — the emergency blanket folding machine.

1. Raw Materials for Emergency Blanket Folding Machine

The production starts with rolls of vacuum aluminized film or PE (polyethylene) film. These materials combine flexibility, heat reflection, and strength.

Each roll is typically DIA≤φ600mm and 1300–1600 mm wide, designed to fit the ZXJ YWJ-JJT-1600 folding machine.

At the start of the line, a pneumatic tailstock feeds the material smoothly into the system. A magnetic brake maintains even tension, preventing wrinkles or tearing. This careful feeding step sets the foundation for precise folding later on.

2. Emergency Blanket Folding Machine Process Step-by-Step

Folding and Fixed-Length Perforation

Once the material enters the folding zone, the process becomes fully automated. The ZXJ machine executes fan-shaped creases across the film’s width and Z-type creases along its length — a blend that guarantees compact storage and effortless unfolding when deployed in the field.

Each fold maintains an accuracy of ±3 mm, even at 60 meters per minute production speed. This precision is made possible by servo-controlled synchronization between the rollers and folding plates.

Continuous Output and Easy Separation Design

In the longitudinal direction, folding and perforation occur simultaneously. The perforation unit performs fixed-length punching, for example, every 1 or 2 meters, depending on the preset product size.

This synchronized operation allows the machine to maintain continuous, high-speed production while forming precise tear lines.

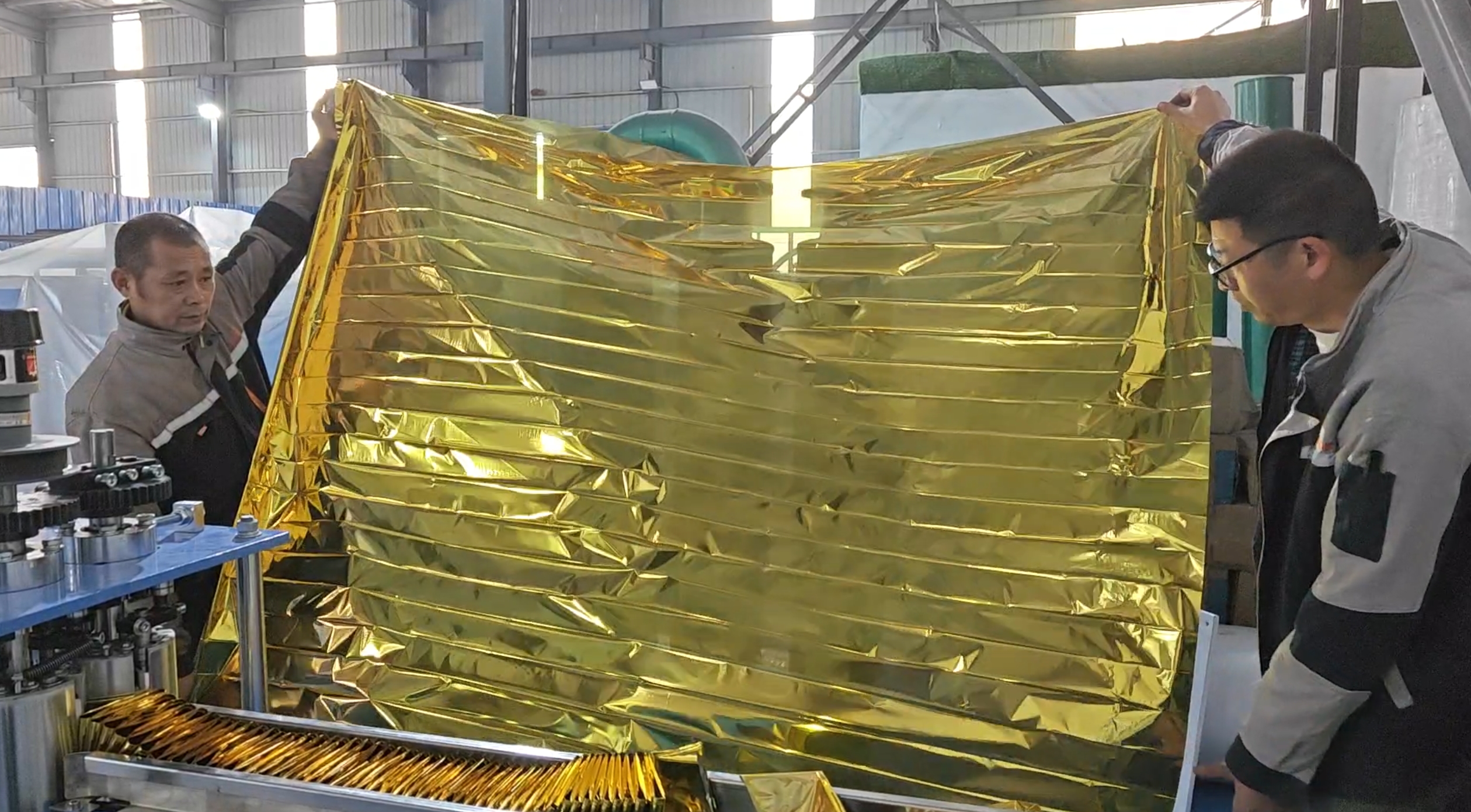

As a result, the finished blankets remain connected as a single strip during output, but each can be easily separated along the perforated line during sorting or manual packaging—creating individual, perfectly sized emergency blankets without interrupting production flow.

3. Manual Packaging and Custom Automation

Once folded, the emergency blankets are ready for packaging. In most production environments, workers manually insert each folded blanket into PE self-sealing bags — the standard packaging method used globally for first-aid supplies.

However, for high-volume production, ZXJ Machinery offers custom-designed packaging lines that bag-sealing systems.

4. Technical Performance and Energy Efficiency

The YWJ-JJT-1600 model operates with 3 kW power and requires an air source of 0.4–0.7 MPa, making it both energy-efficient and environmentally friendly.

Its compact footprint (6200 × 2500 × 1400 mm) allows easy integration into existing production layouts.

Each component — from the vacuum fan to the transmission belt — is engineered for long-term stability, low noise, and minimal maintenance. The result is consistent performance and extended service life, critical for 24/7 industrial use.

5. Patent-Backed Innovation

ZXJ Machinery is the original inventor and patent holder of this folding technology, protected under invention patent CN109677990B (Google Patents).

This patent covers the machine’s unique folding and perforation mechanisms, forming the foundation for modern emergency blanket manufacturing lines.

Today, a significant portion of emergency blankets produced in China and internationally rely on ZXJ’s patented systems. This leadership reflects not only technical innovation but also long-term collaboration with emergency supply manufacturers worldwide.

6. Industry Impact and Future Development

As global demand for emergency medical supplies grows, automation becomes essential.

ZXJ Machinery continues to innovate beyond folding — developing high-speed lines, energy-efficient drives to help manufacturers improve consistency and reduce waste.

Future models aim to integrate real-time monitoring and data tracking, allowing operators to measure output, folding precision, and energy consumption remotely.

Conclusion

The production of emergency blankets is a fine example of how precision engineering meets humanitarian purpose.

From the feeding of delicate films to the final folded form, every stage depends on reliable automation.

ZXJ’s emergency blanket folding machine, backed by patent CN109677990B, remains at the heart of this process — transforming thin reflective films into products that save lives in every corner of the world.

Ready to upgrade your production line with patented folding technology?

Contact ZXJ Machinery today to get a customized solution for your emergency blanket folding machine project.

Or contact our engineering team directly:

WhatsApp: +86 158-9610-9075

Email: paul@zxjmachinery.com