Tissue Paper Manufacturing: Understanding Machine Costs and Starting Production

Introduction

The tissue paper manufacturing industry is a vital sector globally, producing essential hygienic products for daily use. The demand for soft, absorbent paper products like facial tissues, toilet paper, and paper towels is growing. If you’re in or entering this industry, you’ll need to understand how tissue paper is made, what materials are used, and how the global market works.

The Foundation: Raw Materials and Paper Pulp

Suspendisse potenti. Nullam non urna eu nisi hendrerit posuere nec non justo. Sed vitae lectus non augue tincidunt fringilla. Integer in aliquam odio. Curabitur eget libero nec arcu fermentum elementum a non eros. Vivamus convallis, purus nec feugiat tempor, nisi eros varius enim, vel efficitur erat elit id erat. Nunc vehicula lacus sed libero feugiat convallis.

From Materials to Pulp

After sourcing, these materials are turned into paper pulp. This happens through either mechanical or chemical pulping. The pulp’s quality is key, as it directly affects how soft, strong, and absorbent the final tissue product will be.

Global Market and Industry Trends

The tissue paper industry is a dynamic global market, driven by population growth, urbanization, and increasing hygiene awareness. Key trends include the growing demand for sustainable products made from recycled paper, the development of more energy efficient production methods, and innovations in product features like strength and absorbency. Major tissue paper producers are constantly investing in research and development to meet evolving consumer preferences and regulatory standards. The competitive landscape necessitates continuous improvement in paper manufacturing efficiency and product quality.

How Much Do Chinese Tissue Paper Manufacturing Machines Cost?

The cost of tissue paper manufacturing machines from China varies a lot. This is mainly because these machines are highly customizable. Their prices depend heavily on what the customer specifically needs.

Choosing a Production Line

Generally, you can choose between fully automatic and semi-automatic tissue paper production lines.

- Fully Automatic Lines: We recommend these for companies with larger budgets.

- Semi-Automatic Lines: These might be a better fit for businesses with limited funds or those in countries with lower labor costs.

Starting Your Tissue Paper Production Business

So, how do you start a tissue paper production business? The first step is to understand the production machinery. A complete tissue paper production line typically includes:

① Tissue Paper Rewinder: This machine is responsible for feeding raw materials, embossing patterns, applying glue for lamination, perforating the tissue paper (to make it easy to tear), and applying glue for sealing the tail end of the rolls.

② Conveyor Belt: This handles the transportation of products between different stages of the production line, moving items from one processing step to the next.

③ Paper Cutting Machine: This machine is mainly responsible for cutting the rewound paper rolls from the previous step into the desired finished product dimensions.

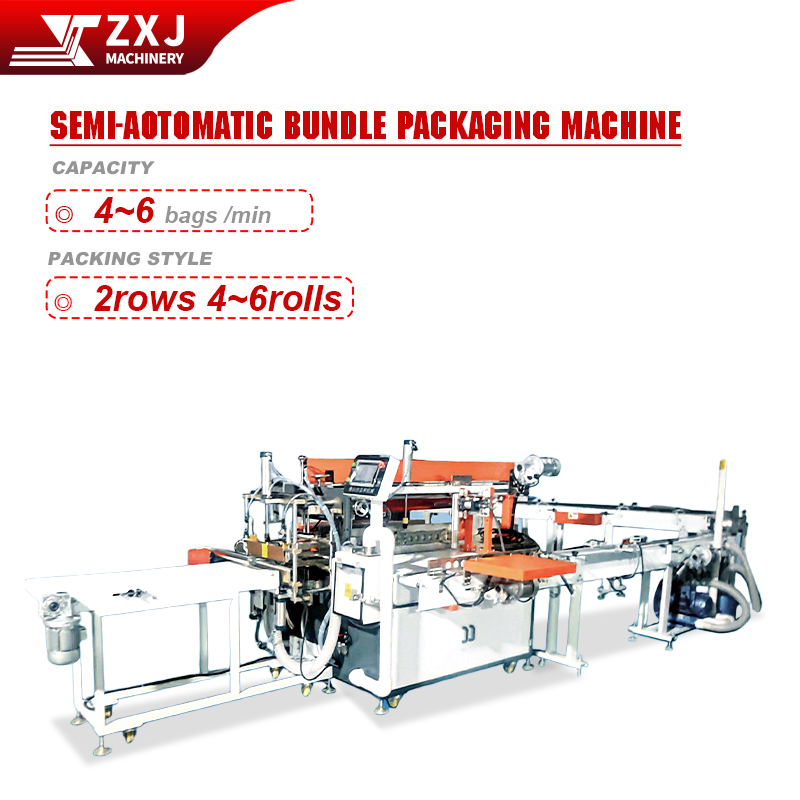

④ Packaging Machine: This machine counts and stacks the cut products and then packages them. Packaging machines can be divided into single-roll packaging machines and multi-roll packaging machines. Multi-roll packaging machines further include semi-automatic and fully automatic middle packing machines.

If you have any questions, please feel free to contact us.

Conclusion

Tissue Paper: A Growing Business

Making tissue paper is a big chance in a growing global market. You’ll want to understand the cost of Chinese machines and how to set up your own production line.

Future of the Industry

The tissue paper industry is focused on being sustainable, working well (efficient), and finding new ways to do things (innovation). This means it’s ready for more growth, meeting the rising need for these important paper products.